Problem Statement

The customer operates four testing furnaces in their R&D laboratory, which are currently controlled using standalone PID controllers. For each heating cycle, operators are required to manually enter the furnace setpoints, heating duration, and other process parameters into the PID controller. This manual setup process is time-consuming and increases the risk of human error.

In case of power interruption or system shutdown, the furnace does not retain the running cycle data. The operators must manually calculate the remaining heating duration and re-enter the parameters into the controller to resume the process. This not only affects the accuracy of R&D trials but also leads to inconsistent heating profiles, impacting product test results and research quality.

To overcome these challenges, the customer wants to digitize and automate the furnace operation. The goal is to implement an automated monitoring and control system for all four furnaces with recipe-based operation, automatic cycle time resumption, and historical data logging. This will eliminate manual input errors, ensure consistent heating cycles, and improve R&D accuracy, traceability, and efficiency.

Solution

Apeiron delivered a complete Solution with,

Control System:

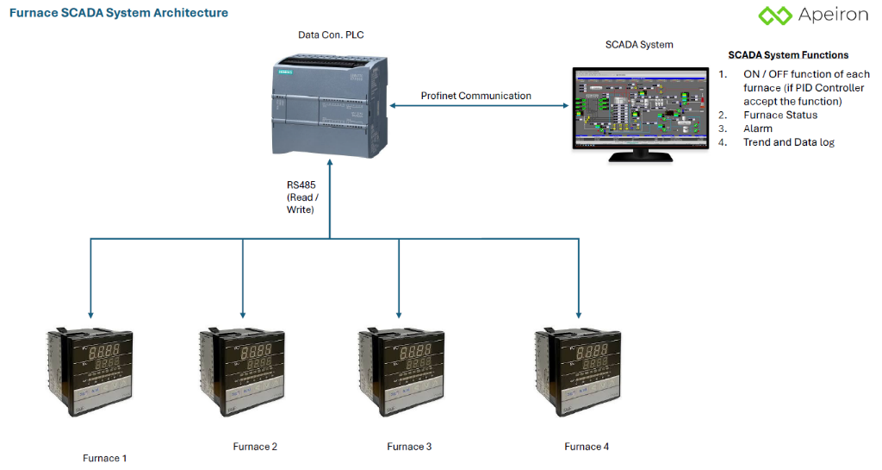

Supply of 1 no’s of Control Panel or Enclosure – Indoor in a closed air-conditioned room. Supply of PLC Controller & Communication Modules to execute the Step Logics.

Centralized SCADA:

Supply of 1 No’s of SCADA system along with Workstation, Monitor & UPS.The System should Primarily consist of Overview Screen for viewing and controlling Step Operations of 4 Temperature Controllers. System should consist of other mandatory screens like Alarms, Architecture, Trend, Data log, etc. as well.SCADA Workstation to be supplied with required Software and Licenses.Testing and Commissioning of New Control System and SCADA

Benefits

- Centralized Recipe Management

- Elimination of Manual Errors

- Automatic Cycle Resumption After Power Failure

- Better Reporting & Analysis