Problem Statement

The automobile manufacturer receives multiple sub-parts from various vendors and assembles them into the final product on the shop floor. However, due to the lack of a proper traceability system, they are unable to track sub-components used in each product or identify which products were shipped to specific customers.

This gap in product and sub-part traceability has resulted in increased customer rejections, difficulty in root-cause analysis, and challenges in quality control and supplier accountability.

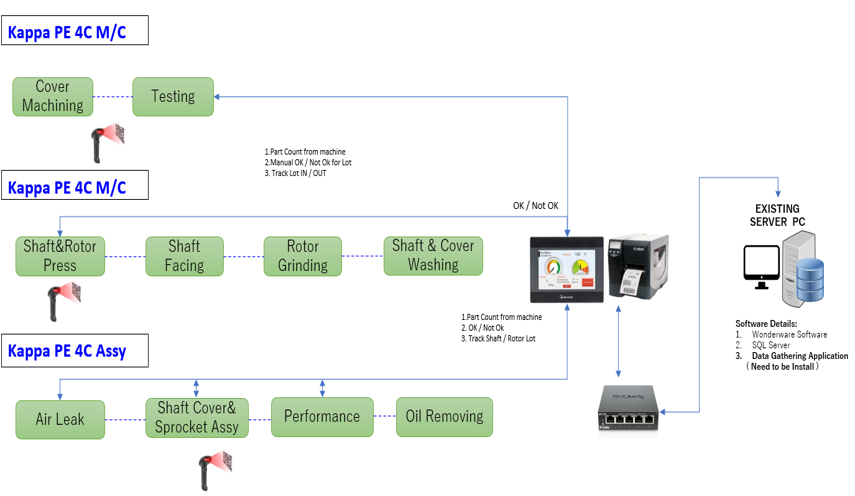

Architecture

Solution

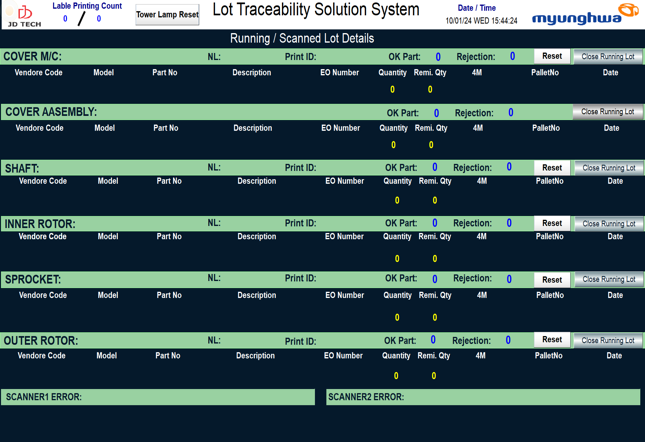

- Apeiron addresses this challenge by implementing a complete end-to-end traceability system using AVEVA software integrated with barcode scanners and printers across RM stores and production lines.

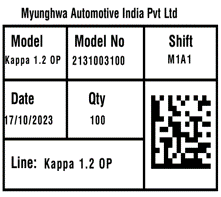

- Barcode generated for each lot/part received from vendors and added to inventory

- Quality team approval captured before material issue

- FIFO-based material issue from RM stores to production

- Each assembly station equipped with a barcode scanner

- Operator scans lot barcode before production start

- System verifies:

- FIFO compliance

- Quality approval

- Production allowed only after validation

- Final barcode generated at the end of the line and applied to finished product

- Final product barcode mapped with all sub-part lot barcodes

Benefits

- Complete forward & backward traceability.

- Elimination of wrong-lot usage & quality escapes.

- Faster root-cause analysis for customer rejections.

- Higher accountability for vendors and assembly operations.