Problem Statement

The customer intends to upgrade the curing machine control system by replacing the existing PLC with the latest PLC technology. They want to achieve this modernisation while retaining the current control panel structure and reusing existing panel components. The challenge lies in ensuring compatibility, seamless integration, and minimum downtime during the upgrade.

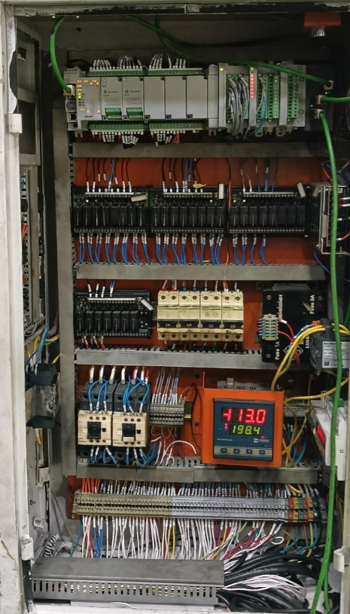

Architecture

Solution

- Apeiron delivered a complete control panel upgrade solution in collaboration with the customer’s electrical team.

- To ensure smooth execution and avoid production delays, two dedicated teams were deployed:

- Team 1: Installed the new PLC-based control panel on the shop floor

- Team 2: Prepared the next control panel in advance for the following machine

- During each shift, Apeiron safely removed the existing panel from the machine, installed the new upgraded panel, and completed all field wiring to bring the machine back into production quickly.

- This phased and parallel execution approach ensured minimal downtime and a seamless transition to the latest PLC system.

Benefits

- Minimal production downtime due to planned phased execution

- Faster upgrade cycle with a two-team deployment strategy

- The reuse of existing panel components reduced the project cost.

- Operational efficiency with a structured installation workflow

- Improved production continuity and reduced disruption to operations